In plumbing and piping systems, selecting the appropriate pipe threads is crucial for ensuring leak-free connections and efficient fluid transport. Two common thread standards used extensively in the industry are NPT (National Pipe Thread) and NPS (Nominal Pipe Size). Each standard has its unique characteristics and applications, making it essential to understand NPT vs. NPS differences and suitability for various projects.

1. What are NPT and NPS Pipe Threads?

NPT (National Pipe Thread): NPT is a U.S. standard for tapered threads used in plumbing and piping systems. The threads are tapered, meaning they gradually get thicker or wider towards the end of the fitting. This design creates a tight seal when the male and female threads are joined together, preventing leaks. NPT threads are commonly used for sealing joints in pipes carrying liquids or gases under pressure. They are available in sizes ranging from 1/8 inch to 4 inches.

NPS (Nominal Pipe Size): NPS refers to the standard nominal pipe size without consideration of thread pitch or diameter. It is a North American standard that specifies the nominal size of pipes based on the outside diameter (OD). NPS threads are straight (parallel), which means the diameter remains consistent along the length of the thread. Unlike NPT threads, NPS threads do not provide a sealing function themselves and require additional sealing methods such as gaskets or O-rings. NPS sizes range from 1/8 inch to 12 inches or larger.

2. Differences in Design and Functionality

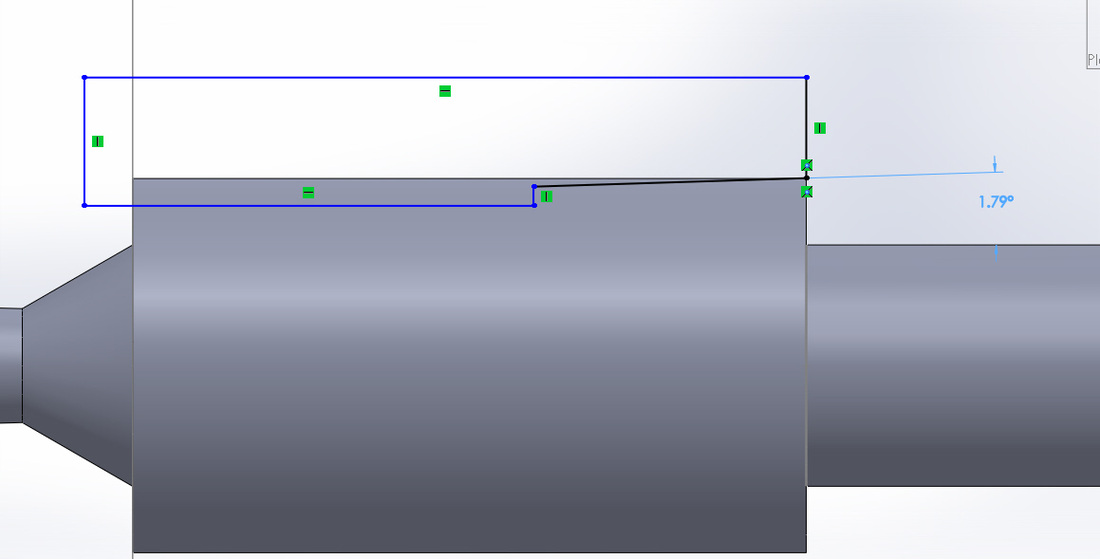

Taper vs. Straight Threads: The primary difference between NPT and NPS threads lies in their design. NPT threads have a taper of approximately 1° 47′ or 1 in 16 on the diameter, which helps in creating a tight seal as the threads are tightened. In contrast, NPS threads are straight and require additional sealing components to prevent leakage. This makes NPT threads suitable for applications where a secure seal is essential, such as in plumbing connections.

Sealing Mechanism: NPT threads rely on the interference fit between the male and female threads to create a seal. As the tapered threads are tightened, they compress together, forming a seal against the flanks of the threads. This design is effective for sealing joints in pipes carrying liquids or gases under pressure, minimizing the risk of leaks. NPS threads, on the other hand, require sealing components like gaskets or O-rings to ensure a leak-free connection, making them suitable for applications where frequent assembly and disassembly are required.

Applications and Usage:

- NPT Threads: Widely used in plumbing, hydraulic systems, and pneumatic applications where a tight seal is critical. Common in fittings such as couplings, elbows, and tees.

- NPS Threads: Commonly found in pipe fittings that require a more flexible sealing method, such as flanges and certain types of valves. Used in applications where precise alignment and sealing reliability are paramount.

3. Practical Considerations for Selection

Environmental Factors: When choosing between NPT and NPS threads, consider the environmental conditions and operational requirements of your project. NPT threads are suitable for applications involving pressurized fluids or gases, thanks to their self-sealing mechanism. NPS threads may be preferred in applications where frequent assembly and disassembly are necessary, as they facilitate easier installation and removal without compromising the integrity of the seal.

Compatibility and Interchangeability: While both NPT and NPS threads are widely used in North America, it’s essential to ensure compatibility between fittings and components. Mixing thread types can lead to leaks or improper connections. Always verify the thread type and size requirements specified by manufacturers and adhere to industry standards to maintain system integrity and performance.

4. Conclusion

Understanding the differences between NPT and NPS pipe threads is essential for selecting the right fittings and ensuring efficient operation of plumbing and piping systems. Whether you opt for NPT threads for their self-sealing capabilities in pressurized applications or NPS threads for their versatility and ease of assembly, each thread type serves specific purposes based on design, functionality, and operational requirements. By considering these factors and adhering to industry standards, you can confidently choose the appropriate pipe threads for your project, ensuring reliable performance and leak-free connections.

iVIGA Faucet Online Shop

iVIGA Faucet Online Shop